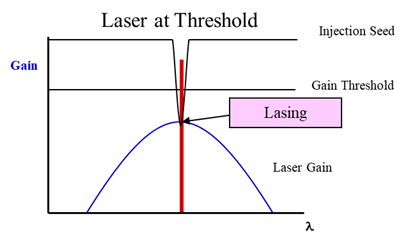

In our last blog post, “Laser Amplification for Power Scaling,” we discussed how an optical amplifier can be used to increase the power of a seed laser while maintaining its performance characteristics. The same basic principle can be applied to a laser itself, with a method known as injection seeding. In this case, a single frequency laser is sent into the laser cavity therefore selectively reducing the gain threshold at that specific frequency as shown in the figure below. This method is can be used with a wide range of different types of lasers, including diode lasers, solid state lasers, and fiber lasers. In this blog, post we are going to look specifically at the use of injection seeding for narrow linewidth pulsed fiber lasers.

The big question then becomes, why would someone want or need to injection seed a pulsed fiber laser. In order to the understand answer to this question, we first need to recognize the fact that the pulsed lasers inherently have broader spectral linewidths than continues wave laser sources. Assuming all other conditions being equal the uncertainty principle itself is responsible for spectral broadening, simply through the act of turning the laser on and off. When you add in all of the other real-world consequences of constructing a q-switched laser (a full analysis of these factors is beyond the scope of this blog post), the spectral bandwidth can quickly balloon out of control. While for most industrial applications such as cutting, welding, and marking this spectral boarding doesn’t factor into the overall system performance making it perfectly acceptable. But, for a more scientific application which requires a precise knowledge of the laser’s wavelength, single frequency seed lasers are commonly used to lock the fiber laser to a desired wavelength.

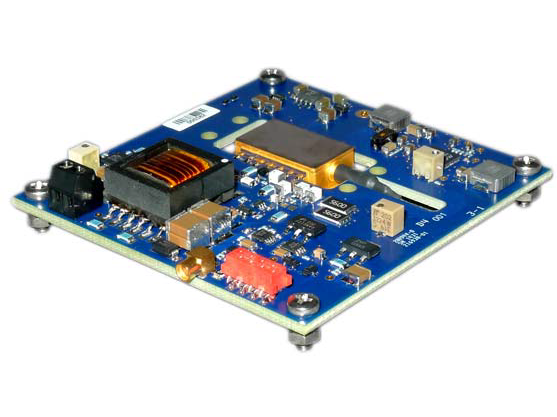

In this case, a single frequency diode laser (typically a single-mode butterfly packaged diode laser), is coupled into the fiber laser optical cavity and pulsed via a gain switching electronic driver board which can be triggered and timed to coincide with the q-switched fiber laser’s pulse. This causes the fiber laser to lock onto the seed lasers exact wavelength due to the reduction in the laser’s gain threshold at that specific wavelength. An example setup with the butterfly package soldered to the pulsed driver board is shown below.

While RPMC has a wide variety of single frequency fiber-coupled diode lasers, the external cavity volume Bragg grating (VBG) diode laser tends to work best for this application. The primary reason for this all relates to the lasers ability to be pulsed at relatively low duty cycles (<100ps) without it negatively impacting the spectral properties of the laser. Additionally, the ability to manufacture VBGs with extremely precise wavelength section capabilities, for example, 1064.1 nm versus 1064.3 nm, allows the laser to be built to your specific wavelength requirements.

At RPMC we offer a wide selection of fiber-coupled single frequency VBG based lasers, as well as the laser driver assemblies with integrated thermoelectric controllers. These drivers have adjustable pulse widths down to 250ps and compliance voltages ranging from 1.2V to 3.0V making them ideal for pulsing red and near-infrared laser diodes.

For detailed technical specifications on our single frequency fiber coupled VBG laser diodes click here and for additional information on our laser driver boards click here. As always you can talk to one of our laser experts today by emailing us at [email protected] or by contacting us Here.

BUY NOW

BUY NOW