Driving a vehicle at night or during foggy conditions can be tricky and dangerous, where poor visibility can cause undue stress or even an accident. These conditions make it more difficult to see upcoming potential obstacles, especially if that obstacle is a deer in a field or a pedestrian in dark clothing at night. Driving at night or in heavy fog can also make a person zone out, feel tired, and perhaps fall asleep at the wheel. However, thanks to newer, more efficient, and cost-effective advancements, we could see more widespread deployment of LIDAR-based automotive detection and warning systems. These systems, which utilize infrared (IR) detectors, could help drivers map the surrounding 3D environment and help detect obstacles such as a stopped vehicle or a pedestrian. Furthermore, they can alert the driver, and even initiate a collision avoidance protocol as part of an active safety system.

Considering the environmental side, one part of the ongoing effort to protect the planet involves humanity figuring out what to do with all our waste. With more and more waste products generated every year, innovations in technology can play a significant role in tackling this problem. When it comes to the challenge of sorting out and recycling various forms of waste that have become intermingled, again, we see infrared detectors stepping in to ease some significant pain points. For example, these detectors can help to rapidly and efficiently differentiate between plastics and paper waste as it zips by on high-speed conveyors. The food industry can also take great advantage of this technology, helping to sort out broken eggs or detect various defects in fruits and vegetables. These and other industries can utilize infrared detectors to assist in the more efficient delivery of goods and produce with a higher level of quality control.

Considering the environmental side, one part of the ongoing effort to protect the planet involves humanity figuring out what to do with all our waste. With more and more waste products generated every year, innovations in technology can play a significant role in tackling this problem. When it comes to the challenge of sorting out and recycling various forms of waste that have become intermingled, again, we see infrared detectors stepping in to ease some significant pain points. For example, these detectors can help to rapidly and efficiently differentiate between plastics and paper waste as it zips by on high-speed conveyors. The food industry can also take great advantage of this technology, helping to sort out broken eggs or detect various defects in fruits and vegetables. These and other industries can utilize infrared detectors to assist in the more efficient delivery of goods and produce with a higher level of quality control.

However, despite great utility in these devices, widespread deployment has likely been hindered by the high cost of traditional InGaAs (indium gallium arsenide) IR detectors. The typical price point was such that the main customers tended to be defense contracts or astronomy applications with the budget to justify the right tools for the job.

|

|

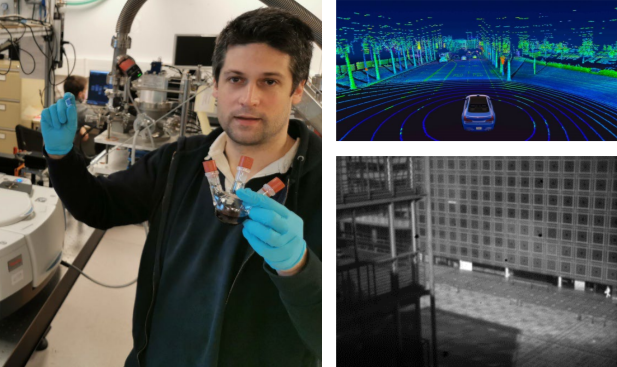

Left: Dr. Emmanuel Lhuillier in his lab, producing low-cost infrared detectors that open new opportunities for applications like night car driving LIDAR air (top-right), plastic waste sorting, egg quality detection, and more. Bottom-right image is an example of an image acquired with a camera whose active layer is made of IR nanocrystals |

Dr. Emmanuel Lhuillier and his team at the Paris Institute of Nanosciences (INSP), the National Centre for Scientific Research (CNRS), and Sorbonne University discovered a solution to this exclusivity problem. The team utilized HgTe (mercury telluride) nanoparticles to help produce much lower-cost IR detectors. For example, a traditional InGaAs sensor costs around 1000 €. A new HgTe detector, on the other hand, only costs around 70 €, a cost difference of more than an order of magnitude! This low price point opens many new possibilities for mass-market applications deployment.

Simpler production processes mainly drive the reasons for this massive cost reduction. Producing HgTe detectors does not require the same very costly Molecular Beam Epitaxy (MBE) equipment or the ultra-high vacuum conditions required to manufacture traditional semiconductor thin films. The production time to manufacture HgTe is also much faster, typically only one day. HgTe involves the production of a solution of nanoparticles in traditional chemistry glassware, like the one held by Emmanuel in the picture in his left hand. He is holding a HgTe detector in his right hand that can be used for infrared sensing.

Emmanuel and his team utilize a 4.4 µm (4400 nm) quantum cascade laser (QCL) system from mirSense that can generate pulse width down to 30 nanoseconds to characterize the response time of their detectors. Their detectors are most responsive in the short-wave infrared (SWIR), but have some responsiveness in the mid-infrared (MWIR), which is where the 4.4 µm laser comes in. Additionally, the QCL system provides the ability to excite some intraband transitions of the nanocrystals (see more on this in the list of publications below).

mirSense QCLs were chosen as the right fit because the driving electronics of these lasers is able to generate pulse widths down to tens of nanoseconds, which is advantageous for the characterization of the response time of their IR detectors.

See Our Full Line of QCLsAlso check out these other mirSense articles:

- Blogs:

Let one of our Product Managers answer any questions, or provide assistance choosing the right laser:

Contact Us here, or email us at [email protected]!

mirSense came into being in 2015 after years of developing the QCL technology, providing mid-infrared (MWIR) and long-infrared (LWIR) range laser sources. They design and manufacture high-power (typically watt-level down to ≈ 100 mW) diodes in 4.0, 4.6, 4.8, and 9.Xµm wavelengths for their PowerMir line and 10-17µm wavelengths for their UniMir line. |

|

BUY NOW

BUY NOW

Have these detectors been commercialized? Where can I get a hold of them?