Solutions Experts

In business for over 20 years, with nearly 10,000 units fielded, the experts at Bright Solutions have built a history of success and have gained a vast amount of applications experience. In their modern applications lab, ideal for proof-of-concept testing and sample processing, they provide a host of DPSS laser configurations with a range of wavelengths and power levels, have a dedicated staff with years of application experience, and even offer process development support.

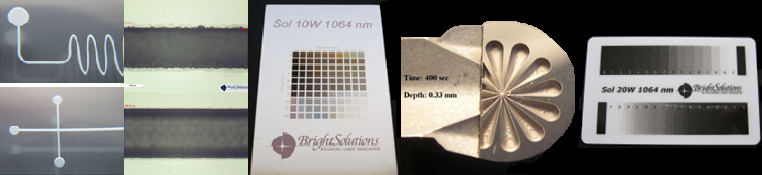

The experience of the applications lab experts covers a broad range of materials and processing techniques. For example, with glass and sapphire, they have demonstrated lens marking, surface engraving, microchannel processing, dicing, hole drilling, and intra-volume marking. They can perform color marking on stainless steel, deep 3D laser milling on synthetic polycrystalline diamond (PCD), micro-hole drilling through nickel iron alloy, gray scale marking on plastics, high contrast marking on heat-sensitive polymeric materials, and many other successful application examples (Click Here to see a presentation detailing their applications experience). However, for this article, we are going to focus on the processing and cutting of printed circuit boards (PCBs) and the laser solutions best equipped to handle this application group.

PCB Processing Know-How

|

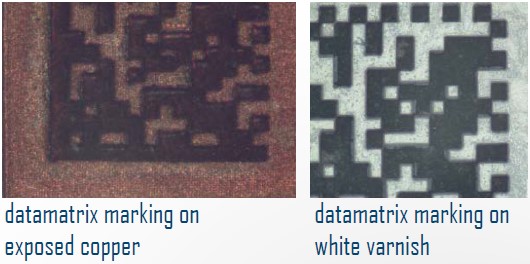

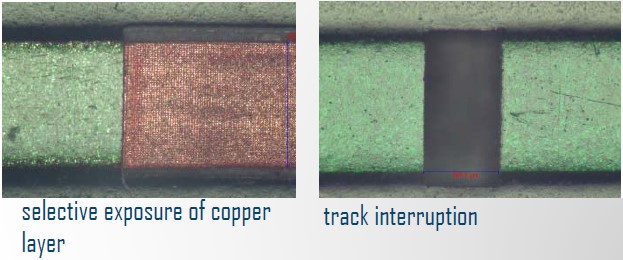

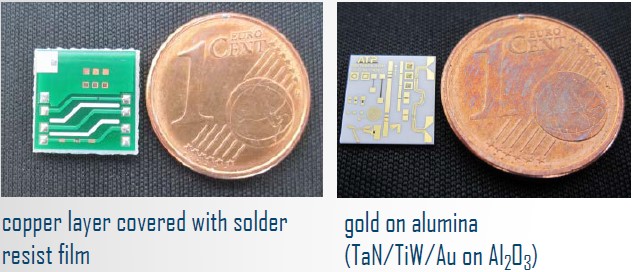

Bright Solutions has extensive PCB experience, with various processing techniques and high-quality system solutions, providing superior results. With their robust systems, you will be able to successfully tackle any PCB processing challenge, from cutting to marking, utilizing the same laser source. Whether needing selective material removal (e.g. solder resist film on copper, or gold on alumina), track interruption (short-circuit), in-situ micro-corrections of connection errors, component termination & separation, or barcode & data matrix marking, Bright Solutions has the right solution for you. |

|

These solutions include a range of compact, air-cooled DPSS lasers with high-energy ns and sub-ns pulses. The single-unit design of these lasers allows for fast and easy replacement in the field, and in the example of the SOL Series – 532nm up to 32W, each model shares the exact same mechanical footprint. Air-cooling, rather than the typical water cooling of other systems, reduces the overall footprint, integration complexity, and maintenance time and cost associated with these lasers. |

|

DPSS Solutions for PCB Processing

|

For rigid FR-4 PCBs up to 1.6mm thickness

For flexible PCBs

|

|

|

Characteristics for Cutting:

Characteristics for Marking:

|

|

Additionally, we offer the MicroMake Plus 532nm, a complete integrated and compact laser micromachining unit for high precision and resolution applications. The MicroMake Plus 532nm provides up to 35kW peak pulse power, 10-100kHz repetition rate, and air cooling, with features such as live imaging of processing area, embedded illumination, down to 2µm spot size, and offers a host of optional add-ons. This complete integrated system includes all the needed devices for direct laser micro-processing in a single monolithic element, perfect for the correction of defects (track interruption / short-circuit) on printed circuit boards.

DPSS vs. Fiber Lasers

Fiber lasers are compact, rugged, reliable, & reasonably priced. So, why choose DPSS over fiber? DPSS lasers provide the same benefits fiber lasers offer, plus a host of additional benefits, allowing the versatility, precision, and quality you need for a vast range of applications. The DPSS lasers from Bright Solutions boast a rugged, fixed laser cavity design, resulting in a compact and reliable laser. Shorter pulse widths inherent to DPSS lasers result in higher peak powers with less heat affected zone (HAZ). With integrated doubling and tripling harmonic crystals, DPSS lasers enable easy access to more wavelength options (e.g. 532nm) and therefore, more application capabilities. Finally, Bright Solutions continuously improve their products and offer extensive customization to further benefit your application.

For more technical information on the lasers discussed in this article, click the links below:

Talk to a knowledgeable Product Manager today by calling us at 636.272.7227, or by clicking the link below!

The Bright Solutions Group consists of 4 business units: Bright Solutions, Bright Microlaser, Bright Systems, and Bright Aerospace.

BUY NOW

BUY NOW