Approximately half of the laser diodes that we provide here at RPMC Lasers are fiber-coupled. For this reason, we have decided to build upon our recent two-part blog on fiber coupling in our Laser Diode Fundamentals series by exploring the differences between pigtailed laser diodes and fiber-coupled laser diodes. To understand the differences, first, it is helpful for us to review core diameter, which is an important principle discussed in the first part of our fiber coupling series. When thinking about a fiber’s core, it is useful to separate them into two different categories single-mode and multimode.

For single-mode fibers the core diameter needs to be tiny, typically less than 10 microns, to ensure that no higher-order modes can propagate through the fiber. On the other hand, multi-mode fibers can have a wide range of core diameters ranging from 62.5 microns upward on 1 mm. Both of these fiber types are widely used with laser diodes depending on the needs of the application. For example, when the beam profile is essential, such as in microscopy, single-mode fiber is almost always preferred. By contrast in an application, such as laser cladding, where power is most important a multi-mode fiber would be the obvious choice.

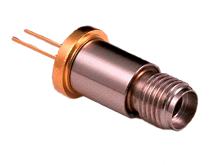

Based on the small size of the core diameter, it is easy to see that a major pro of the pigtailed approach is alignment stability. In part two of our fundamentals series, we discussed how laser manufacturers utilize micro-positioning stages while the power output from the distal end is monitored to ensure optimal fiber coupling. When using a detachable fiber such as in the laser package shown below, it is impossible to ensure that each time the fiber is connected, it will line up in the same spot, reducing the overall coupling efficiency of the system.

That being said, pigtailed laser diodes suffer from a significant drawback; if the fiber is damaged it cannot be replaced without sending it back to the manufacturer for repair. In fact, in some cases, such as with hermetically sealed laser packages even if you send the laser back to the manufacturer, they may not be able to open the package without causing irreparable damage. For single-mode and smaller core multimode fibers, with proper handling, a fiber will rarely break, but as the size of the fiber increases so does the risk of damaging it. This is because the minimum bend radius of a fiber is defined as 150 times its cladding diameter. As a result, a typical 105/125 multimode fiber can be bent in a 3.5 cm loop with no problems, but a large core 600/660 multi-mode fiber can break if looped tighter than 18 cm. Therefore, large-core multimode fiber-coupled diode lasers are typically detachable for easy replacement.

Lastly, when choosing between pigtailed and detachable fibers, you must also take the laser power level into consideration. Everyone understands that the fiber coupling process of a laser diode is not 100% efficient, and this means that the “lost power,” which doesn’t make it into the fiber has to go somewhere. When dealing with high power laser, this “lost power” can quickly heat up the proximal end of the fiber requiring adequate heat sinking. Generally speaking, when a diode laser is pigtailed, it is rather hard to heatsink the fiber tip properly often leading to mechanical failures. By using a detachable fiber, the connector itself can serve to heat sink the tip, reducing the risk of overheating.

It is also important to note that many laser diode systems will utilize a combination of the pigtailed and detachable fibers to get the best of both worlds. In these systems, one or more diodes are internally fiber coupled with a permanently pigtailed fiber and then terminated at a bulkhead connector which is fed through the case — allowing for an external detachable fiber to be connected and replaced while maintaining the internal coupling efficacy. The two diode laser systems shown below are examples of this approach.

Next month we will continue our discussion of fiber-coupled diodes, examining the beam properties of single and multimode fibers, as well as how to choose the right focusing / collimating optics for your application. In the meantime, if you would like to get more detailed information on the fiber-coupled diode lasers offered here at RPMC Lasers, click here or, you can also talk to one of our laser experts today by calling 1-636-272-7227.

BUY NOW

BUY NOW