We recently updated a blog post titled “Target Designation Laser Source Requirements,” in which we took a deep dive into the fundamentals of laser designation as well as the military’s requirements for such a laser. In that blog post we cited NATO standard STANAG 3733, which required that the laser beam have a divergence small enough so that 90% of its energy is on target 95% of the time assuming a 2.3 x 2.3 m target. We went on to explain that most laser designators are designed to be used at distances up to 5 km. Therefore, one of the most critical factors when choosing a laser source is the beam divergence.

Larger Beam Smaller Spot Size – How Beam Size Impacts Divergence

In this post, we are discussing one method for decreasing the beam divergence by increasing the beam size. While this may seem counter-intuitive, it is, in fact, the case that as the collimated beam diameter increases, the beam divergence decreases. This happens for the same reason that a laser diode has a slow and fast axis. That is, whenever light is contained in a small area, it tends to diffract or diverge. The same process happens to the laser beam itself. If a laser is perfectly collimated it is considered to be diffraction limited. This means that the laser beams divergence is solely determined by the area it is confined in, hence its beam diameter. Therefore, when you expand the laser beam to a larger diameter and re-collimate it the divergence will decrease since the light isn’t being squeezed into as small of an area as it once was. As a general rule of thumb, the beam divergence is inversely proportional to the beam diameter. So, every time you double the beam diameter you half the beam divergence.

Choosing the Right Beam Expander for Your Application

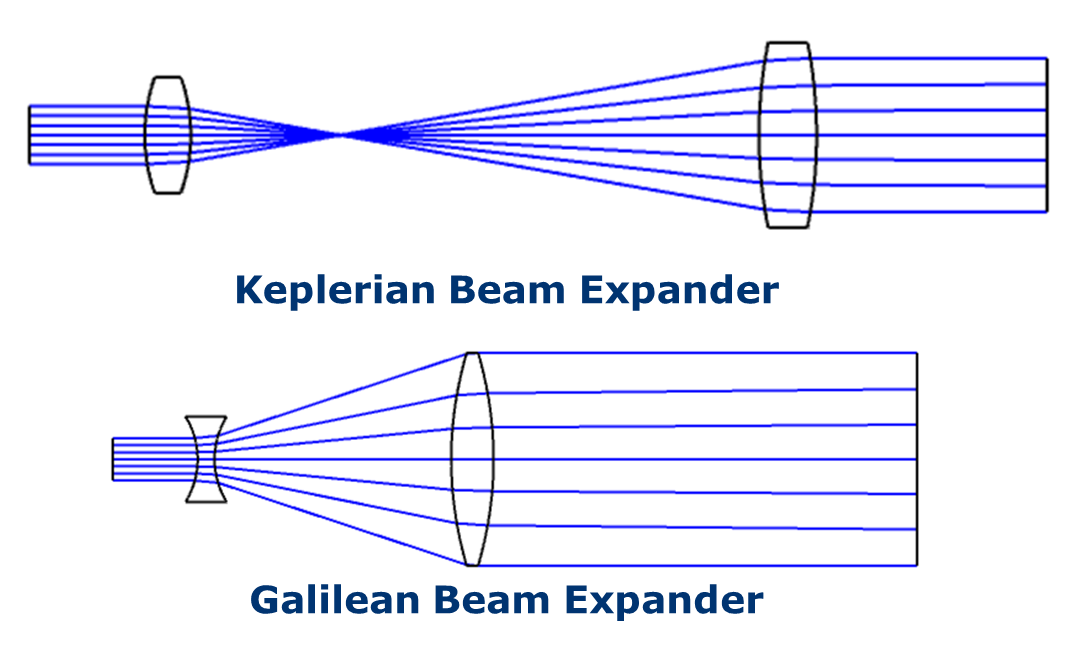

In laser designation, you can take advantage of this fact, to ensure a smaller spot size on the target by starting out with a larger beam exiting the designator. Two primary beam expander designs are used today, Keplerian and Galilean. From the image below you can see that the fundamental difference between these two designs is the existence of an intermediate focus. While the Keplerian design can be beneficial for lower power applications such as microscopy, for most high power and field-deployable applications the Galilean design is far superior. The Galilean is preferred in applications such as laser designation not only because it is more compact, but also because it doesn’t run the risk of thermal instabilities due to heating from the intermediate focus.

Larger Beam Smaller Spot Size – Calculating Beam Divergence

While using a beam expander is an excellent way to decrease the beam divergence and ensure a longer range (smaller spot at a distance) for laser designation it is still imperative that you start out with as low a beam divergence laser as possible. For example, a pulsed DPSS laser with a beam parameter produced (BPP) of approximately 6 mm-mrad, means that at a beam diameter of 6mm the laser will have a beam divergence of 1 mrad. Therefore, if this laser beam was expanded to a collimated diameter of 24 mm it would have a beam divergence of 0.25 mrad. By definition a mrad means that after 1 m the radius of the beam will increase by 1 mm, so this means that at a distance of 5 km our beam (with a 0.25 mrad divergence) will be approximately 2.5 m in diameter. Which is more than acceptable for the NATO guidelines.

MegaWatt Lasers offers cutting-edge, Made-in-the-USA laser solutions. The ER902 Eye-Safe Miniature Solid-State Laser, designed for defense and aerospace applications, delivers high-peak power at the “eye-safe” 1.5 µm wavelength, making it ideal for range finding, LIDAR, and target designation. Built in a contaminant-free cleanroom environment and engineered for rugged, long-term reliability, this compact, ultra-low SWaP laser operates in extreme conditions, providing consistent performance in the harshest environments. With a wide operating temperature range and backed by decades of expertise from a dedicated team of physicists and engineers, the ER902 combines precision, power, and safety in a lightweight design. As a trusted partner, RPMC ensures quick shipping, no tariffs, and comprehensive support—from initial setup to ongoing maintenance—ensuring your project’s long-term success.

Here at RPMC lasers, we have teamed up with industry-leading partners to introduce the Kaukas & Ranger (Optogama) and ER902 (MegaWatt) into the laser designation market. For additional information, including detailed technical specifications, talk to one of our knowledgeable Product Managers today:

Talk to one of our knowledgeable Product Managers today by emailing us at [email protected] or Contact Us with the button below!

Have questions?

BUY NOW

BUY NOW