| For security purposes, ID cards often require some form of unique identifier and tamper-proof security features, designed to mitigate the potential for alteration and counterfeiting. Laser sources play an essential role in this regard, providing a means to create permanent, high-quality, and tamper-proof marks on polymeric cards. Typically, the ID cards are a multi-layer composition of poly-carbonate and PVC, with select pigments added to the inner layers of the card during fabrication. When combined with the high peak power pulses generated by Q-switched, DPSS laser sources, these additives provide highly efficient absorption of 1064nm radiation, changing the color of the inner layers of the card without affecting the top transparent layer. This process provides the capability of producing a high-quality mark, protected from counterfeiting, since the inner layer is not accessible. |

|

| The light-matter interactions between a laser source and specific plastic or polymer compositions produce a durable and high-contrast mark. Typical laser marking processes (e.g. vector or raster/bitmap marking) are suitable for colored, white, or black plastic materials when marking a logo, text lines, and DataMatrix/bar codes. While raster/bitmap marking is used to create gray scale photos and graphics. In the latter example, using laser-sensitive additives (pigments) in plastics can generate considerable advantages in terms of contrast and efficient absorption. Bright Solutions provides several laser products tailored to different applications, according to the material composition that has to be processed. |

| One such laser product to consider, the SOL 10W 1064nm from Bright Solutions, is a standard and versatile solution for vector and raster/bitmap marking. With its short pulse duration (from 10 up to 50 ns) and excellent beam quality, the SOL can create a permanent, protected, non-tactile, high-quality mark on the inner pigmented layer of the plastic cards without heating or alterations to the top layer. |  |

|

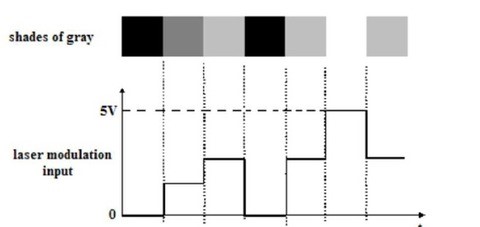

To create gray scale images with the SOL laser, a fast output power modulation is needed. This rapid pulse energy modulation is achieved by connecting a dedicated input signal, present in the I/O electronic interface of the laser, to an analog output port of the marking hardware. Pulse energy can be modulated from 0 to 5V, according to software commands. The pulse energy modulation input, directly connected with the internal Q-Switch modulation circuitry, allows for varying the laser pulse energy without changing pumping power and repetition rate signals. This unique feature allows the creation of a quality gray scale curve with a direct correlation between each level of gray to a specific value of laser pulse energy. The result is a high-quality, repeatable gray scale image (up to 600 dpi of resolution) with an impressive rate of production. |

Other Bright Solutions’ lasers suitable for this application include the One 1030nm and Onda 1064nm:

- The extreme compactness (only 13 x 7 x 4 cm³ size and 0.5 kg weight) of the One 1030nm makes it the perfect solution for low-cost desktop machines with tight integration tolerances. While the achievable photo resolution is the same as Sol 1064nm (up to 600 dpi), the rate of productivity is lower.

- Alternatively, the Onda 1064nm, providing a shorter pulse duration range (2 to 10 ns) and a superior beam quality, can be focused tightly on ID cards, achieving higher resolution (up to 1000 dpi) without heating the samples.

Let one of our Product Managers answer any questions, or provide assistance choosing the right laser by calling us at 636.272.7227, or Contact Us here!

SHIPS TODAY

SHIPS TODAY